Feed is the top expense for cattle operations, accounting for approximately 70% of direct cow-calf enterprise expenses.1 Pasture rent and ownership are one aspect of feed costs, with purchased and raised feed making up the remainder of the costs.

In 2022, improving the management of all three areas can enhance the profitability of the cattle operation.

Management Considerations

- Manage pastures.

Manage pasture for maximum quality, quantity and grazing duration. Letting the animal be responsible for the forage harvest reduces supplemental feed costs. Evaluate grazing plans for the 2022 season. Make the plan accommodate different grass species, rotation plans and available water resources. The plan also needs to consider recovery, especially if the pasture was over-utilized during last year’s dry weather. Make sure to consider all grazing animals when making the plan. Also, keep in mind changes in the animal unit throughout the year (cow with young non-grazing calf, pairs with older grazing calves, weaned cows, stockers/yearlings). - Hay storage.

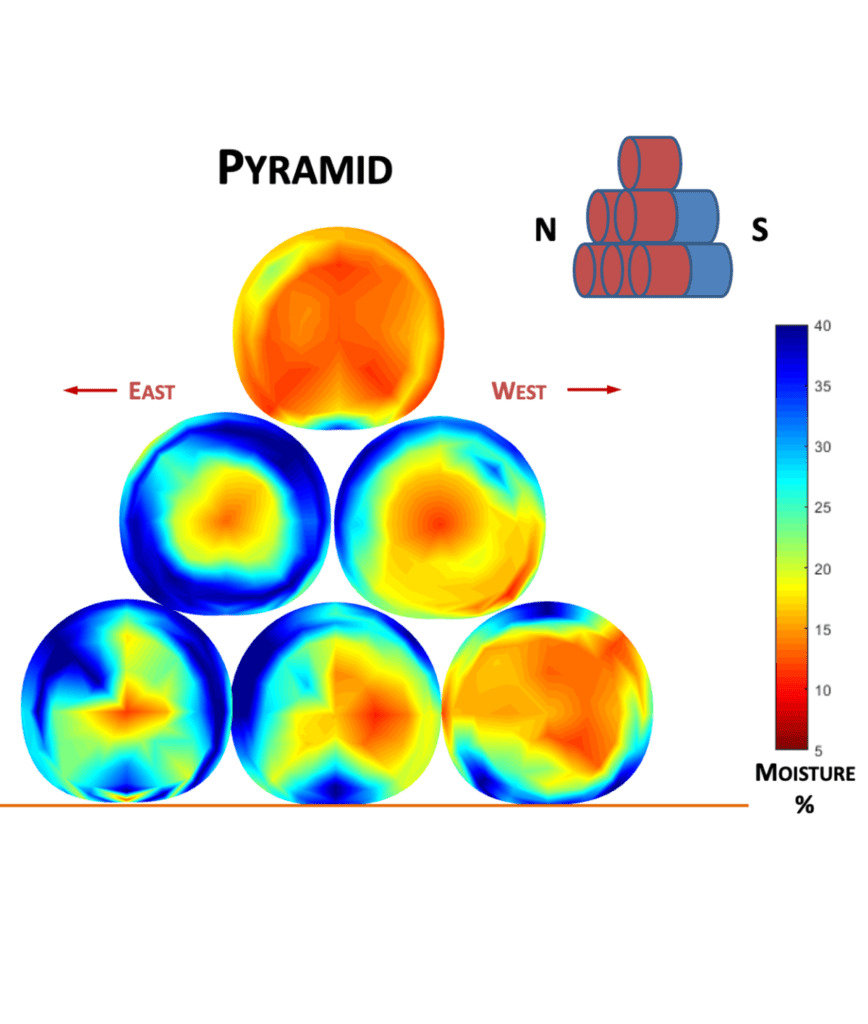

Putting up hay and alfalfa is an expensive and time-consuming process. Properly storing the harvested forage is crucial to maintaining the quality and quantity of the bales. When bale use should guide how the feed is stored. Bales stored for a short period can be stacked two or three bales high without losing much feed quality. However, if the bales have the potential of being held over to the following spring or summer, storing the bales in long rows, with space between the rows, will reduce the losses in both quality and quantity.2 Bales left to “melt” in the field are a detriment to the profitability of the operation. - Utilization.

Taking feed tests provides information on the protein and feed values of the bales. Use the data to feed according to the dietary requirements of the animals. The feed test also allows ration formulation changes as the cow or calf’s nutritional needs change due to reproductive changes or growth. - Feed efficiently.

Feed loss due to the feeding method is a significant expense many producers do not consider. There is a substantial variation in the feed loss depending on the method used. Hay rolled out, put into different types of hay feeders, or ground, varies in the amount of feed waste. Hay waste savings can offset the initial expense of upgrading feeding equipment. For example, if your hay feeder allows for 20%waste at $200 per-ton, there is $26 worth of feed lost with every bale fed.3

In Summary

Feed is expensive and sometimes hard to find. Pasture prices, harvest expenses, hauling and waste add to the total feed bill. Evaluate your forage situation this winter and make changes that improve your profitability.

References

- Fin-Bin data for 2020 South Dakota, North Dakota, and Nebraska Cow-calf operations, the report ran 1/6/2022

- Round Bale Storage Conservation, SDSU Extension 2020

- Moore and Sexton (2015), University of Missouri Agriculture Experiment station, found open bottom hay feeders had 19.2% waste, tapered feeders had 13.6% waste, and cone feeders had 8.9% waste.

SOURCE: SD State University Extension

Updated January 21, 2022

Heather Gessner

SDSU Extension Livestock Business Management Field Specialist