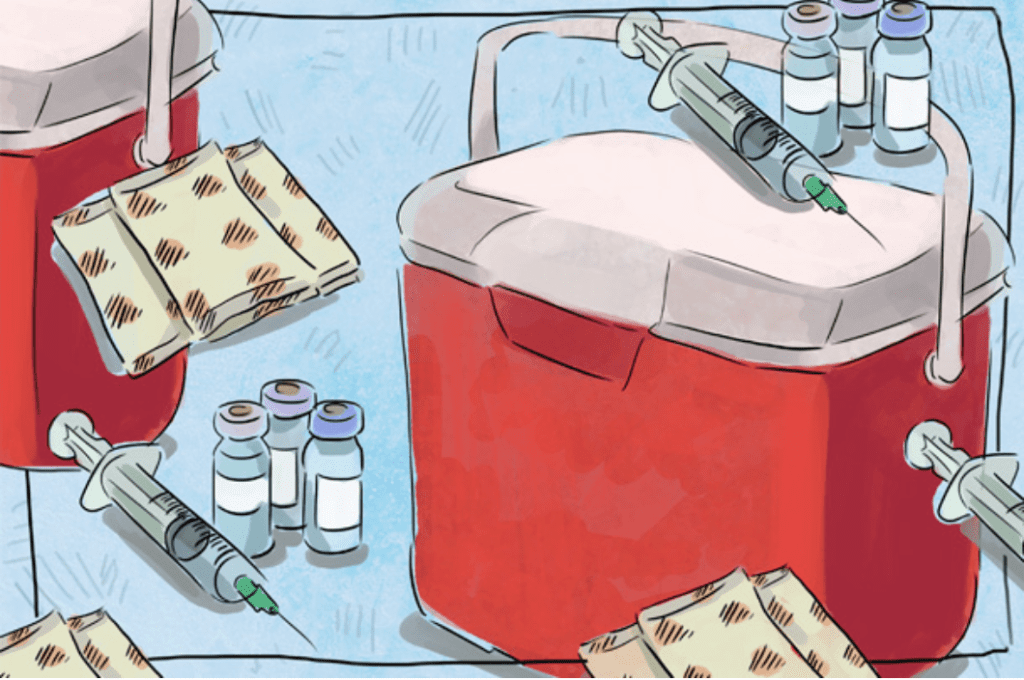

Keep your injectables safe and effective when working cows in the winter.

While labels on most injectables say they require refrigeration, our cold-weather winters are just a little too cold. But since beef production is 24-7, 365 days a year at all temperatures, we need to figure out how to keep our injectables at the proper temperature.

As you read a label, if an injectable needs to be kept cool, that usually means between 35º to 45ºF. Anything below that is too cold and could damage the product and lower its effectiveness. The last thing you want is to have to doctor an animal a second time because round one didn’t work or to get to the corrals and discover you now have ice crystals in your injectable.

Good news, there are some simple solutions to this problem. Setting your injectables on the defroster or under the heater in the pickup is not the solution. In fact, if you leave it there too long, you could be “cooking” it and damaging the product that way.

Several Lemhi County, Idaho, cattle producers calve in late January, early February. This means they are vaccinating against scours in December. December can be cold in Lemhi County, and I wanted to help them keep their vaccines at the proper temperature. So, that led me to doing my own “warm” cooler demonstration. I gathered empty vaccine bottles and refilled them with water. I then gathered various type of coolers and utilized temperature loggers to log the temperatures inside the coolers. As I thought through various ways to keep something warm, I focused on items I thought most ranchers could find in their kitchens. I settled on pint jars with lids for my mini demonstration. You can also use rice heat sacks that you can pop into the microwave. The caution with these is to not set your injectable directly on top of them. Place some towels between so the bottom of the bottles do not become hot. You could also use disposable hand warmers that have instant heat. Again, do not place the injectable directly on top of these.

By tracking the outside temperature and the cooler temperature, I determined three key practices to keep your injectables from being too cold:

- Start with a warm cooler. Bring your cooler into the house and let it warm up before using it. If you forget this step, fill the cooler with hot water and let it stand for a while, then dump the water out.

- If the outside temperature is between 35º and 45ºF, you can place your injectables in the warm cooler.

- If the outside temperature is below 32ºF, add a closed pint jar of hot tap water to the cooler. If you have a quality cooler it will hold the warmth for an hour or two. I define a quality cooler as being hard sided or a heavy Styrofoam cooler, such as they ship vaccine in. Soft-sided coolers do not maintain temperature.

So, you made it to your working facilities with your injectables at the correct temperature; now load the syringe and give the injection. Depending on how many head you are injecting, you can handle this a couple of different ways. If it is closer to 0ºF than not, you may consider having a second cooler to transport and store your syringes in. The last thing you want is ice crystals in the needle. Pack extra needles so if this does happen you can put on a fresh needle. If you only have a few head to inject, consider loading each dose individually so you know they are receiving the correct dosage. If you are doing a large number of animals and using a multidose syringe, you are going to have to get creative to keep everything warm. One idea is to use the finger off an extra-large glove. Make a slit in the end of the finger for the needle and then slide this over the barrel of the syringe. You will not be able to see how much product is left in the syringe easily, but it will help maintain the temperature. If someone on your operation is handy with a sewing machine, they could sew a pocket on the inside of a coat or vest that you could slip the syringe into, utilizing your body heat to help maintain the temperature. Just be sure to cap the needle so you don’t accidently get vaccinated.

Keeping injectables at the proper temperature is vitally important so they maintain their effectiveness. During the cold season, this can provide a unique challenge, but by thinking ahead (bringing the cooler into the house) and being a little creative (building a glove for the syringe), it can be done.

ILLUSTRATION: Illustration by Corey Lewis

SOURCE: Shannon Williams for Progressive Cattle